Thank you for choosing Lightware’s Room Automation Panel series device. In the first chapter we would like to introduce the device, highlighting the most important features in the coming sections.

1.1. Description

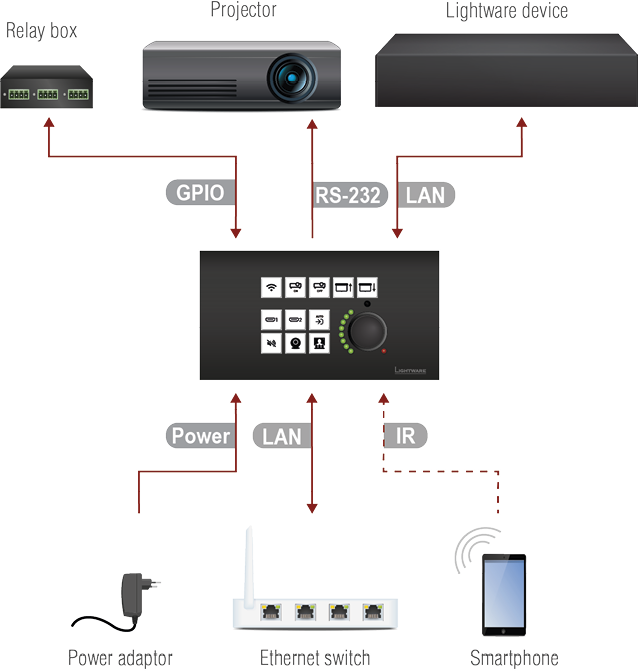

Room Automation Panel is an integrated control solution for AV systems installed in collaborative spaces. It features a programmable keypad, a volume knob, and a processor running Lightware Event Manager.

The stylish unit is available in different sizes and colors which fit EU, US and UK electrical boxes and tabletop enclosures. Rear panel RS-232, 3xGPIO and 2xRJ-45 ports provide connection to controlled devices. Snap-on front cover and PoE receiver of the first RJ-45 connector make the installation smooth. The additional RJ-45 connector makes cabling flexible and can supply PoE when an AC adapter is plugged in.

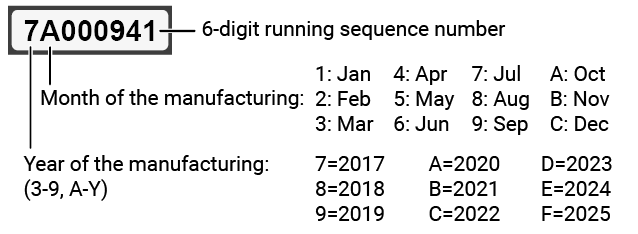

Model Denomination

Lightware devices contain a label indicating the unique serial number of the product. The structure is the following:

1.2. Model Comparison

1.2.1. Comparison of RAP and RAC Models

|

RAP-B511 series |

RAC-B501 |

|

|

User interface |

11 configurable buttons & jog dial control knob |

1 configurable button & 1 configurable feedback LED |

|

Wall mountable |

|

|

|

Rack mountable |

|

|

|

Recommended application |

Auditorium; Conference rooms, Office meeting rooms; Operation centers, Residential |

Fixed install venue; Live events, Office meeting rooms |

1.2.2. Comparison of RAP-B511 Series Models

INFO:All models have the same look and functionality, the difference is the size and color of the enclosure.

|

Model name |

Color |

Outlet box type |

|

|

RAP-B511-EU-K |

|

black |

Double EU wall box (65mm) |

|

RAP-B511-EU-W |

|

white |

|

|

RAP-B511-EU-S |

|

brushed steel |

|

|

RAP-B511-UK-K |

|

black |

Double UK wall box |

|

RAP-B511-UK-W |

|

white |

|

|

RAP-B511-UK-S |

|

brushed steel |

|

|

RAP-B511-US-K |

|

black |

Double US wall box |

|

RAP-B511-US-W |

|

white |

|

|

RAP-B511-US-S |

|

brushed steel |

|

1.3. Compatible Devices

Room automation panel has standard RS-232, Ethernet and GPIO ports which are compatible with other Lightware products or third-party devices which have the same signal type.

1.4. Box Contents

1.4.1. Supplied Accessories

The following table describes all supplied accessories of the Room Automation Devices by models

|

Supplied devices |

Supplied accessories |

||||||

|

|

|

|

|

|

|

|

|

RAP-B511 series device |

RAC-B501 device |

Safety and warranty info; QSG |

Phoenix® Combicon 3-pole connector |

Phoenix® Combicon 4-pole connector |

Labels for button caps |

Transparent button caps in a plastic bag * |

|

|

RAP-B511-EU-K |

|

|

|

|

|

|

|

|

RAP-B511-EU-W |

|

|

|

|

|

|

|

|

RAP-B511-EU-S |

|

|

|

|

|

|

|

|

RAP-B511-UK-K |

|

|

|

|

|

|

|

|

RAP-B511-UK-W |

|

|

|

|

|

|

|

|

RAP-B511-UK-S |

|

|

|

|

|

|

|

|

RAP-B511-US-K |

|

|

|

|

|

|

|

|

RAP-B511-US-W |

|

|

|

|

|

|

|

|

RAP-B511-US-S |

|

|

|

|

|

|

|

|

RAC-B501 #new |

|

|

|

|

|

|

|

* The transparent caps are not placed onto the buttons, thus, you can easily insert the desired labels and fix the caps – see the Label and Cap Fixation section.

1.4.2. Optional Accessories

The following table describes all supplied and optional accessories of the Room Automation Devices by models. The optional (not-supplied) accessories can be purchased separately; please contact sales@lightware.com.

|

Optional accessories |

|||||||

.png)

|

.png)

|

|

|

|

|

|

|

|

48V DC adaptor with 2-pole Phoenix® plug |

USB cable (mini-B - USB-A) |

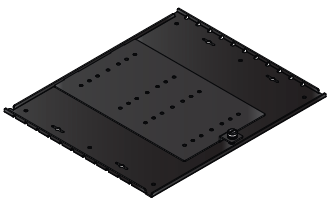

1U high rack shelf |

UD Mounting Plate F110 |

UD Mounting Plate F120 |

UD Mounting Pro P110 |

UD Mounting Pro P140 |

|

|

RAP-B511-EU-K |

|

|

- |

- |

- |

- |

- |

|

RAP-B511-EU-W |

|

|

- |

- |

- |

- |

- |

|

RAP-B511-EU-S |

|

|

- |

- |

- |

- |

- |

|

RAP-B511-UK-K |

|

|

- |

- |

- |

- |

- |

|

RAP-B511-UK-W |

|

|

- |

- |

- |

- |

- |

|

RAP-B511-UK-S |

|

|

- |

- |

- |

- |

- |

|

RAP-B511-US-K |

|

|

- |

- |

- |

- |

- |

|

RAP-B511-US-W |

|

|

- |

- |

- |

- |

- |

|

RAP-B511-US-S |

|

|

- |

- |

- |

- |

- |

|

RAC-B501 #new |

|

- |

|

|

|

|

|

Basic Features

|

Built-in Event Manager |

|

The Event Manager tool takes care of all the necessary control in a smaller configuration by performing predefined actions in response to device status changes. Hence, in a less complex environment, there is no need to invest in additional control solutions, which makes the receiver the best choice for numerous applications. |

|

|

Ethernet Control |

|

Multiple simultaneous TCP/IP connections are available with a simple ASCII-based protocol for controlling, configuring the device or perform a firmware update. |

|

|

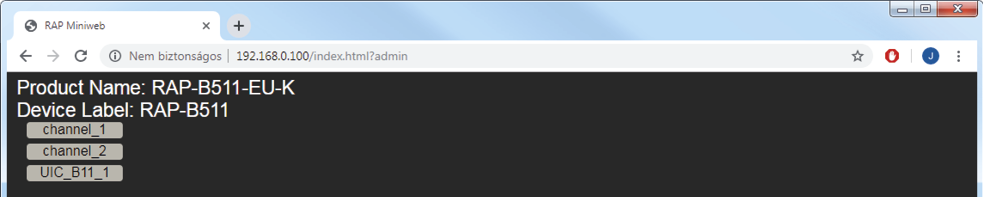

Built-in Mini Web |

|

The Miniweb is able to display an adaptive surface of a virtual front panel, advanced web page displays buttons for Event manager Actions. |

|

|

Remote Power |

|

The RAP-B511 is PoE-compatible and can be powered locally by the supplied power adaptor, or remotely via the TPS connection (through the CATx cable) with a compatible power source equipment, e.g. MMX6x2-HT series matrix switchers and TPS2 matrix boards. |

|

|

Bi-directional RS-232 Pass-through |

|

AV systems can also contain serial port controllers and controlled devices. Serial port pass-through supports any unit that works with standard RS-232. |

|

|

RS-232 Recognizer |

|

Support recognizing incoming RS-232 messages to integrate with 3rd party devices or Lightware units. |

|

|

GPIO Control Port |

|

3 GPIO pins operating at TTL digital signal levels and can be controlled with both LW2 and LW3 commands. |

|

|

LDC |

|

The Lightware Device Controller (LDC) application keeps receiving updates, adding new features and tools. The latest edition of LDC has gotten more intuitive, user friendly, smarter and has a modern user interface. The LDC is available for both Windows and macOS operating systems. |

|

|

|

Real-time clock |

|

Real-time clock with network time protocol and automatic daylight saving adjustment for Event Manager scheduling. |

Only for RAP-B511 series

|

Front Panel Buttons and Rotary Knob |

|

Integrated keypad with 11 programmable backlight buttons. Volume rotary knob to control Lightware devices, TVs or Power Amplifiers volume. |

|

|

Infra |

|

Infrared (IR) is a wireless technology used for device communication over short ranges. Third party control systems may send IR control commands to endpoints turning them on and off or switching their inputs. |

Advanced Control Pack v3

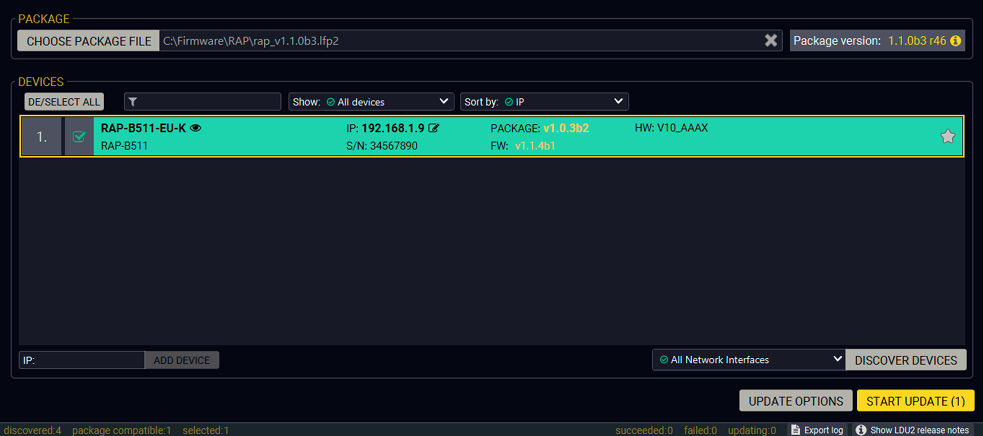

DIFFERENCE:The following features are available from firmware package v1.1.0b3.

|

Basic IT-security |

|

These entry-level network security improvements help to prevent unauthorized access to the Lightware device: cleartext login, TCP port blocking and MAC address filtering. |

|

|

Batch Commands |

|

A batch of LW3 commands (salvo) can be run by the Lightware device either by a previously stored macro or by sending a file to the device with the desired commands. |

|

|

Event Manager + |

|

Triggering a condition, defining variables and checking four conditions for an action – these features are available by the improved Event Manager. |

|

|

TCP Recognizer |

|

Support recognizing the incoming TCP messages to integrate with 3rd party devices like the video conference codec devices. |

1.6. Typical Applications

VINX Application Example

Meeting Room Application Example

Conference Room Application Example

Classroom Application Exampe

The following sections are about the physical structure of the device, input/output ports and connectors, buttons and status LEDs.

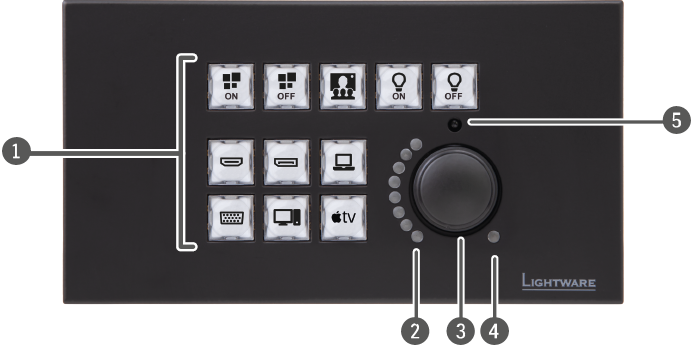

2.1.1. Front View

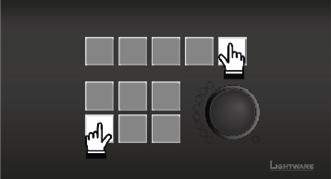

INFO:All the models have the same look and controls on the front panel, the only difference is the size and the color of the enclosure.

INFO:The labels of the buttons are just for illustration since the button caps are empty by default. The user can insert the desired label from the attached sheet.

|

|

Buttons |

11 configurable buttons with short and long press detection. Each button has a programmable background light. They can be configured for immediate feedback of pushing the buttons or can be set to five different modes: |

||

|

|

Rotary LEDs |

Eight green-colored LEDs for giving feedback about the current position of the jog dial knob. |

||

|

full bright |

As the jog dial is rotated right (and the volume increases), the LEDs turn on one-by-one. One level means half brightness. The picture on the left shows that the volume is set 11. |

||

|

half bright |

|||

|

off |

|||

|

|

Rotary knob |

Jog dial for volume control on a 16-level scale or it can be programmed for other controlling purposes by turning and clicking the knob. |

||

|

|

Mute LED |

It gives feedback about the mute status of the volume. It can be toggled on and off by pushing the rotary knob. |

||

|

on |

The volume is muted. |

||

|

off |

The volume is unmuted. |

||

|

blinking |

The device is in bootload mode. Press the rotary knob for 5 sec for changing to the normal operation mode. |

||

|

|

IR detector |

Built-in IR eye to receive infra signal. |

||

|

|

GPIO |

4-pole Phoenix® connector for configurable general purpose. |

|

|

RS-232 port |

3-pole Phoenix® connector for bi-directional serial communication. |

|

|

DC Input |

The device can be powered by a local adaptor. Connect the output to the 2-pole Phoenix® connector. For more information about the powering, see Powering Options section. |

|

|

Ethernet ports |

Two RJ45 connectors for Ethernet communication. Both of them are PoE-compatible, one is a PoE receiver, the other can send PoE (PoE sending is available when the device is locally powered). |

2.2. RAC-B501

2.2.1. Front View

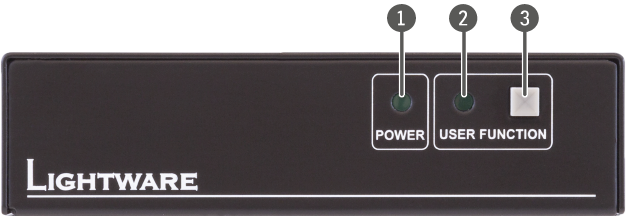

|

|

Power LED |

The LED gives immediate feedback about the current power status of the device. |

||

|

off |

The device is not powered. |

||

|

blinking (green) |

The device is powered on. |

||

|

|

User LED |

Configurable user LED for action feedback purpose. |

||

|

|

Function button |

Special functions are available with the button (DHCP settings, restore factory default settings, condition launching in Event Manager). |

||

2.2.2. Rear View

|

|

GPIO port |

4-pole Phoenix® connector for configurable general purpose. |

|

|

RS-232 port |

3-pole Phoenix® connector for bi-directional serial communication. |

|

|

DC input |

The device can be powered by a local adaptor. For more information see the Powering Options section. |

|

|

Ethernet port with PoE input support |

RJ45 connector for Ethernet communication. The port is PoE-compatible to receive power from a remote device |

|

|

Ethernet port with PoE output support |

RJ45 connector for Ethernet communication. The port is PoE-compatible to send power to a remote device. |

2.3. Special Functions for RAP-B511 Series

2.3.1. Behind the Front Panel

After removing the front plate (no special tool needed, just pull apart by hand), a USB connector, a reset button, and a live led can be seen.

|

|

USB Port |

USB mini-B connector can be used for LDC access or firmware update. |

||

|

|

Reset Button |

Hidden button to restart the device. |

||

|

|

Factory defeault |

Hidden button to reload the Factory Default Settings. |

||

|

|

Live LED |

|

blinking |

The unit is powered and ready to use. |

|

on |

The device is powered, but the CPU is not running. |

||

|

off |

The unit is NOT powered or out of operation. |

||

DIFFERENCE:The hidden button for reloading the factory default settings is available from HW v1.1.

2.3.2. Restarting the Device

Step 1.Keep the 5th and the 9th button pressed for 10 seconds.

Step 2.Release the buttons. The mute LED lights up when the device restarts.

2.3.3. Entering Bootload Mode

It may happen that the firmware update process is unsuccessful and the device cannot be switched to bootload mode automatically. In this case, the device can be forced into bootload mode as follows:

Step 1.Make sure the device is powered off.

Step 2.Press and keep pressed the Rotary knob.

Step 3.Power on the RAP-B511 while the Rotary knob is being pressed. If the device is switched to bootload mode the Mute LED is blinking quickly. Release the knob.

The other LEDs are off. The procedure of firmware update can be found in the Firmware Update chapter.

INFO:Press the rotary for 5 sec to switch the normal operation mode.

2.4. Special Functions for RAC-B501

2.4.1. Programmable Function Button

Action or an operation can be assigned to the Function button as this button press is a condition that can be selected in the Event Manager. See more details in the Event Manager section.

2.4.2. Programmable User LED

Action or an operation can be assigned to the User LED as a condition is fulfilled and the LED responds on that. See more details in the Event Manager section.

2.4.3. Dynamic IP (DHCP) Settings

The device has a static IP address as a factory default setting. If this setting does not fit to the circumstances during install or usage, DHCP can be enabled from the front panel:

Step 1.Make sure the device is powered on and operational.

Step 2.Press and keep pressed the Function button for 5 seconds.

Step 3.After 5 seconds front panel LEDs start blinking; release the button and press it 3 times again quickly (within 3 seconds).

Step 4.The LEDs get dark, DHCP gets enabled. #network #dhcp

2.4.4. Recalling Factory Default Settings

To restore factory default values, do the following steps: #factory

Step 1.Make sure the device is powered on and operational.

Step 2.Press, and keep pressing the Function button for 10 seconds. After 5 seconds the front panel LEDs start blinking, but keep on pressing the button.

Step 3.After 10 seconds the LEDs start blinking faster; release the button and press it 3 times again quickly (within 3 seconds).

Step 4.The LEDs get dark, the device restores the Factory Default Settings and reboots.

#new

The chapter is about the installation of the device and connecting to other appliances, presenting also the mounting options and further assembly steps.

3.1. Mounting Options for RAP-B511 Series

The caps of the buttons are supplied separately with the product in a plastic bag. The list of supplied labels can be seen in the Supplied Button Labels for RAP-B511 series section. Select the desired label and insert it as shown in attached figure:

Step 1.Insert the label.

Step 2.Place the cap and pay attention to the nut; the direction of the buttons are different, thus, certain caps must be rotated by 90°.

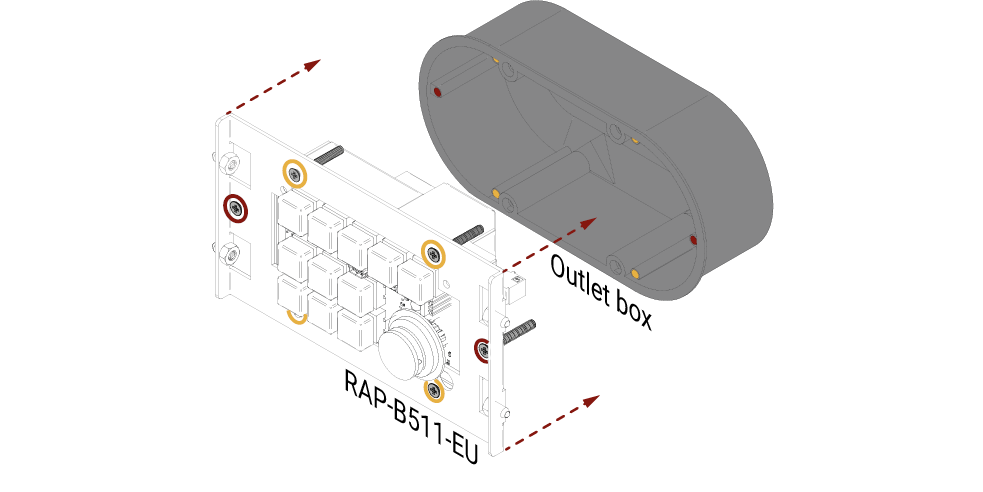

3.1.2. Compatible Outlet Box Types

The room automation panel can be easily mounted into an industrial standard switch/outlet box. See more details about the exact sizes of the device in the Mechanical Drawings section.

Model name refers to the box type, see the recommended box types for the models in the table below:

|

Model |

Outlet box type |

|

RAP-B511-EU |

Double EU wall box (65mm) (e.g. Legrand: 0 801 22, 0 800 52, 2x0 801 51, 2x0 801 61, 0 819 42) |

|

RAP-B511-UK |

Double UK wall box (e.g. Appleby SB628 Galvanised Steel Knockout boxes 2G 47mm) |

|

RAP-B511-US |

Double US wall box (e.g. Carlon B225R-UPC Switch/Outlet Box, 2-Gang, Depth: 2-3/4”) |

INFO:The outlet box is not supplied with the product, it can be purchased from the local hardware store.

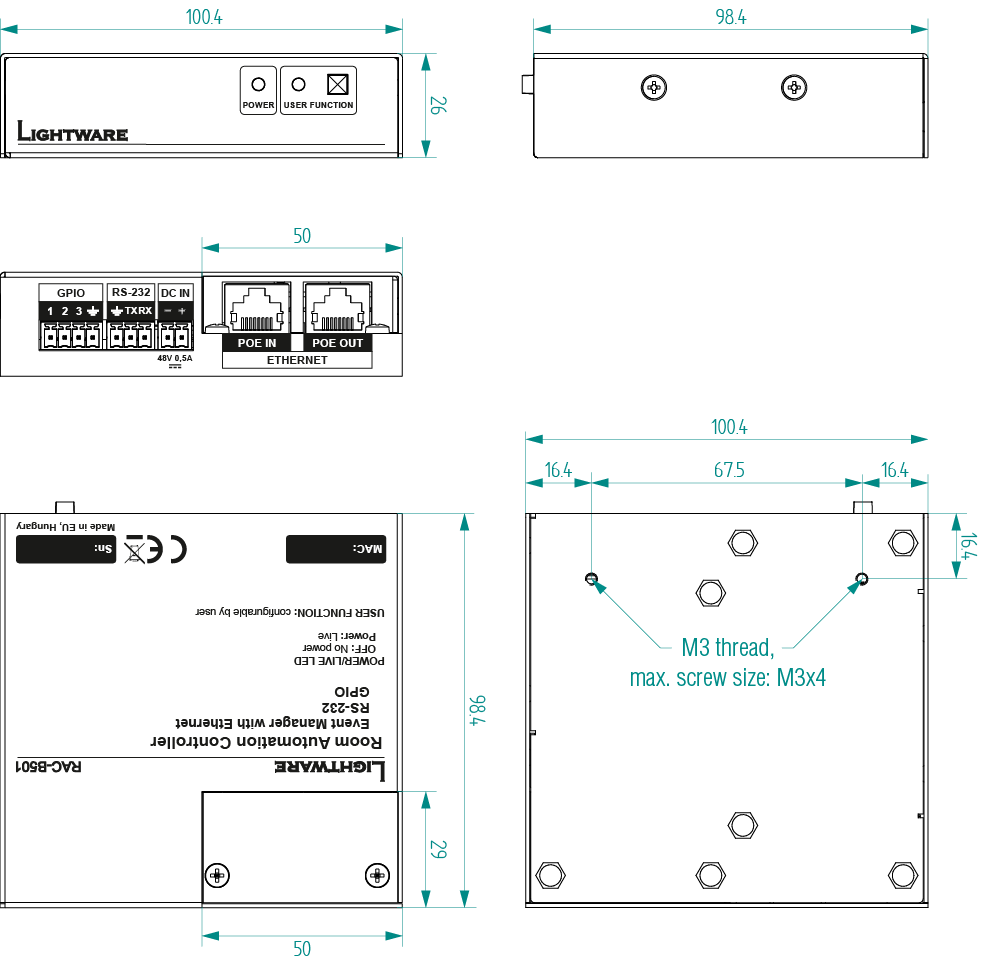

3.1.3. Dimensions

|

Model |

Dimensions (mm) |

|||

|

a |

b |

c1 |

c2 |

|

|

RAP-B511-EU |

152 |

82 |

40.5 |

17.6 |

|

RAP-B511-UK |

140 |

80 |

40.5 |

17.6 |

|

RAP-B511-US |

115.9 |

115.9 |

40.5 |

17.6 |

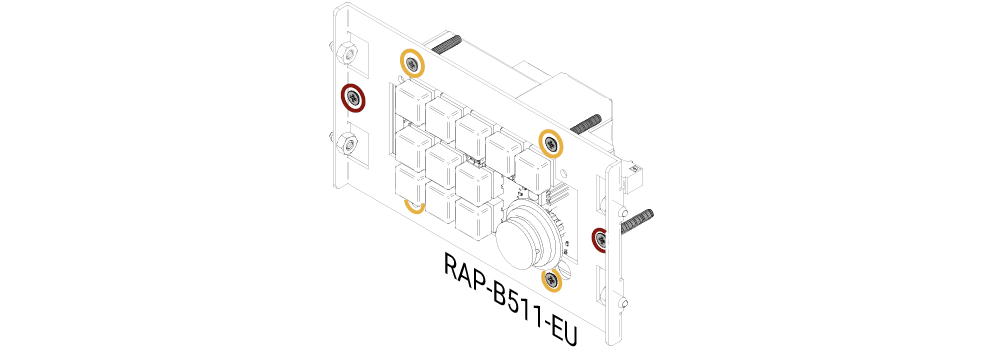

3.1.4. Mounting RAP-B511-EU into the Outlet Box

Step 1.Pull apart the Front plate from the RAP-B511-EU by hand (no special tool needed).

Step 2.Place two screws (marked with red color) OR four screws (marked with yellow color) in the holes.

Step 3.Insert the RAP-B511-EU into the Outlet box and position it to get the holes aligned.

Step 4.Fasten the front side of the device to the Outlet box by fitting all the screws.

Step 5.Place back the Front plate to the Button panel.

See more details about the exact sizes of the RAP-B511-EU in the Mechanical Drawings section.

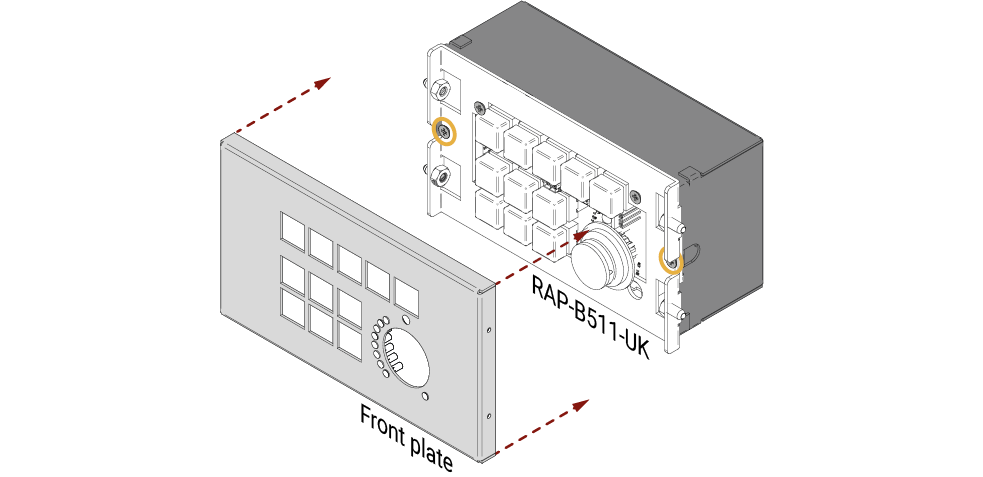

3.1.5. Mounting RAP-B511-UK into the Outlet Box

Step 1.Pull apart the Front plate from the RAP-B511-UK by hand (no special tool needed).

Step 2.Place the screws (marked with yellow) in the holes.

Step 3.Insert the RAP-B511-UK into the Outlet box and position it to get the holes aligned.

Step 4.Fasten the front side of the device to the Outlet box by fitting all the screws.

Step 5.Place back the Front plate to the RAP-B511-UK

See more details about the exact sizes of the RAP-B511-UK in the Mechanical Drawings section.

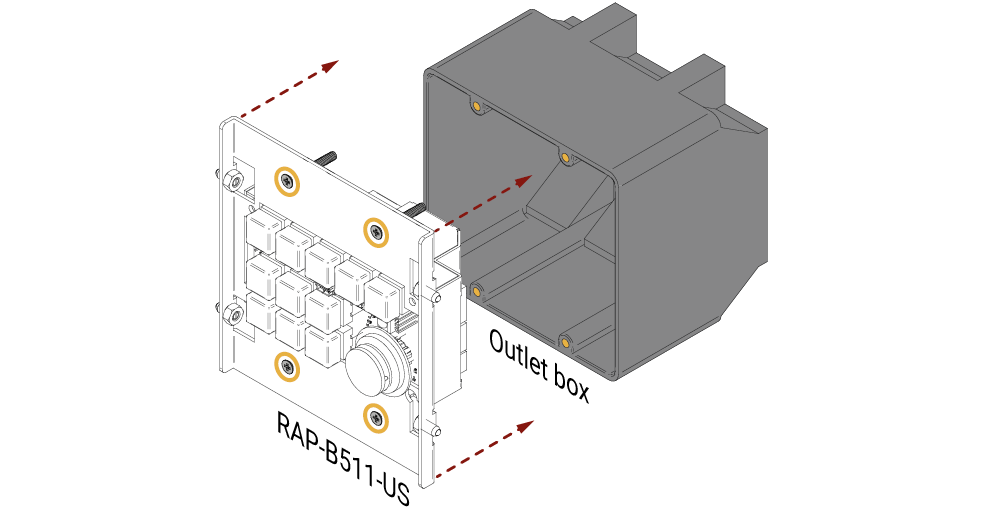

3.1.6. Mounting RAP-B511-US into the Outlet Box

Step 1.Pull apart the Front plate from the RAP-B511-US by hand (no special tool needed).

Step 2.Place four screws (marked with yellow) in the holes.

Step 3.Insert the RAP-B511-US into the Outlet box and position it to get the holes aligned.

Step 4.Fasten the front side of the device to the Outlet box by fitting all the screws.

Step 5.Place back the Front plate to the RAP-B511-US

See more details about the exact sizes of the RAP-B511-US in the Mechanical Drawings section.

3.2. Mounting Options for RAC-B501

3.2.1. Rack Shelf Mounting

DIFFERENCE:Only RAC-B501 model can be installed to a rack shelf.

Allows rack mounting for half-rack, quarter-rack and pocket sized units.

1U high rack shelf provides mounting holes for fastening two half-rack or four quarter-rack sized units. Pocket sized devices can also be fastened on the self.

WARNING!Always use M3x4 screws for fastening the device to the rack shelf. Using different (e.g. longer) ones may cause damage to the device.

INFO:The screws for the rack frame are not supplied to the device.

3.2.2. Under-Desk Mounting

DIFFERENCE:Only RAC-B501 model can be installed under a desk or furniture.

|

Accessory |

Number of mountable devices |

Features |

|

|

UD Mounting Plate F110 |

|

1 quarter-rack sized |

Lightweight design |

|

UD Mounting Plate F120 |

|

2 quarter-rack sized |

Lightweight design |

|

UD Mounting Pro P110 |

|

1 quarter-rack sized |

Easy to change the mounted device |

|

UD Mounting Pro P140 |

|

2 quarter-rack sized |

Easy to change the mounted devices |

INFO:For more details about the options of the applications and the assembly steps, please download the Mounting Accessory Guide from our website: https://lightware.com/pub/media/lightware/filedownloader/file/Assembly-Guide/Mounting_AG.pdf

#new

3.3. Electrical Connections

3.3.1. 48V DC Connection

RAP-B511 series is built with 2-pole Phoenix connector for 48V DC 1A power connection.

2-pole Phoenix connector and plug pin assignments

3.3.2. GPIO - General Purpose Input/Output Ports

RAP-B511 series contains a 4-pole Phoenix connector with three GPIO pins, which operates at TTL digital signal levels and can be set to high or low level (Push-Pull). The direction of the pins can be input or output (adjustable). Voltage ranges for GPIO inputs are the following:

|

Input voltage [V] |

Output voltage [V] |

Max. output current [mA] |

|

|

Logical low level |

0 - 0.8 |

0 - 0.5V |

30 |

|

Logical high level |

2 - 5 |

4.5 - 5V |

18 |

GPIO connector and plug pin assignments

INFO:The maximum total current for the three GPIO pins is 180 mA.

Compatible plug type

Phoenix® Combicon series (3.5mm pitch 4-pole), type: MC 1.5/8-ST-3.5.

3.3.3. USB Connector

Behind the front panel there is a standard USB mini-B receptacle.

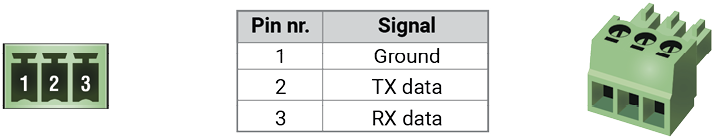

The device contains a 3-pole Phoenix connector which is designed for RS-232 serial connection.

RS-232 connector pin assignments

RS-232 Output Voltage Levels

▪Logic low level: 3V .. 15V

▪Logic high level: -15V .. -3V

Compatible Plug Type

Phoenix® Combicon series (3.5mm pitch, 3-pole), type: MC 1.5/3-ST-3.5.

You can find more information about RS-232 in Settings for Control Interfaces section.

INFO:The RAP-B511 series operates as a DCE unit according to its pin-out.

The room automation panel is supplied an RJ-45 connector for Ethernet/LAN connection for local control functions.

Wiring of LAN Cables

Lightware recommends the termination of LAN cables on the basis of TIA/EIA T 568 A or TIA/EIA T 568 B standards.

RAP-B511 series and RAC-B501 automation panels are compatible with IEEE 802.3af standard - Power over Ethernet (PoE) - and one Ethernet port can receive and the other one can send power over the Ethernet line.

The room automation panel can be powered by any of the following ways:

Local adaptor and remote power (PoE OUT)

When it is locally supplied with 48V DC adaptor, the room automation panel is able to send remote power via POE OUT RJ45 connector to other PoE-compatible device.

Remote power injector (PoE IN)

The devices can be powered remotely by a PoE-compatible power injector, like a PoE-compatible switch. Connect it to the POE IN labeled RJ45 connector.

Standalone Matrix or Matrix board (PoE IN)

Powering by a matrix board* over the CATx (TPS) cable. The output board needs to be powered by an external PSU. Connect it to the POE IN labeled RJ45 connector.

* TPS2 I/O board with PoE extension (-P)

INFO:Over the CATx cable, the Ethernet communication is transmitted.

|

Local adaptor and |

Remote power injector (PoE in) |

Matrix board (PoE in) |

|

||

3.5. Connecting Steps

|

|

Connect a controller/controlled device (e.g. relay box) to the GPIO port. |

|

|

For RS-232 extension: connect a controller/controlled device (e.g. Projector) to the RS-232 port. |

|

|

▪Connect the device to a LAN network in order to control the device. ▪Connect a PoE-compatible device for remote powering and control to the PoE out LAN port. |

|

|

Built-in infra detector is ready to receive any IR signal without user intervention. |

|

|

Powering on the devices is recommended to do as the final step during the installation. Please check the Powering Options section for the details. |

DIFFERENCE:Infrared connection is only available for RAP-B511 series panels. RAC-B501 is not built with IR detector.

The following chapter describes the features of the device with a few real-life examples.

4.1. General Concept

Room automation panel is designed for advanced control functions. Industrial standard communication interfaces (RS-232, Ethernet, GPIO, IR) ensure the compatibility with third-party units or Lightware products. They make automating the whole AV system in a huddle room possible.

Customizing the control functions can be done by making connections between the proper inputs (triggers or conditions) and the desired outputs (actions). These settings can be done from a computer using the Software Control - Lightware Device Controller (LDC) software or via LW3 protocol commands (for more details see LW3 Programmers’ Reference section).

Inputs may come from:

▪The Room Automation Panel by pushing (or releasing) the button, turning or pushing the rotary switch. *

▪Real-Time Clock (e.g. when the local time is equal 12:00 the action is executed).

▪Other incoming signals: detected IR codes, recognized RS-232 messages, GPIO level changes.

Outputs can be the followings:

▪Button LEDs of the Room Automation Panel. *

▪Send messages (or signals) to the other device: RS-232 message sending, TPC/UDP message sending, GPIO output state changing.

* Only for RAP-B511 series models.

4.2. Inputs 1. - User Interactions

DIFFERENCE:This section relates to RAP-B511 series models only. RAC-B501 model is not built with buttons and rotary switch.

The operation of the RAP-B511 series is based on user interactions such as button press, or turn the rotary. These are the main triggers (or inputs) of the control functions. They can be quickly and easily customize in UI Config Menu of the Software Control - Lightware Device Controller (LDC) software.

The RAP-B511 has 11 configurable buttons, and two main button states are defined: Pressed and Released.

Operation mode is an attribution of the button, which declares the button behavior when it is pressed or released. Three different operation modes are available: momentary, toggle and radio group (1-5).

The chosen operation mode defines how the interaction state changes when the button is pressed or released (see the details about it in the table on the right). The true or false value of the interaction state triggers the button LED function and the desired action.

Momentary operation mode

Simple button function, when the button is pressed, the action will be executed.

Example: Roll down the shades with keeping the button pressed. When the button is released, the shades stop.

Explanation: When the button is pressed, the interaction state changes true, when the button is released, the interaction state changes false.

Toggle operation mode

This button type toggles between two states.

Example: Turn on and off the light with one button.

Explanation: When the button is pressed, the interaction state changes true, when the button is released, the interaction state does not change. When the button is pressed once again, the interaction state changes false.

Radio group operation mode

It defines the assigned radio group of the button. One button can belong to one group at the same time. Five groups are available, one group may contain max. 11 buttons.

Example: Select video input on a crosspoint or switcher. One input can be active at the same time.

Explanation: When the button is pressed, the interaction state changes true and the interaction state of the other group members are false. When the button is released, the interaction state does not change.

Summary of the button operation modes

|

Momentary Operation Mode |

||||

|

PRESS |

RELEASE |

PRESS |

RELEASE |

|

|

|

|

|

|

|

interaction state |

||||

|

true |

false |

true |

false |

|

|

Toggle Operation Mode |

||||

|

PRESS |

RELEASE |

PRESS |

RELEASE |

|

|

|

|

|

|

|

interaction state |

||||

|

true |

true |

false |

false |

|

|

Radio Group Operation Mode |

||||

|

PRESS |

RELEASE |

PRESS |

RELEASE |

|

|

|

|

|

|

|

interaction state |

||||

|

true false false |

true false false |

false true false |

false true false |

|

Flowchart of the button configuration process

INFO:All settings of the button functions are available in the Lightware Device Contoller software (see the details in Buttons section) or via LW3 protocol commands (for more details see Button Configuration section).

4.2.2. Rotary

The jog dial knob is designed for volume control (in a 16-level scale), but it can be used for other controlling purposes, too.

Turning left and right the rotary changes the volume value from 0 to 16. The volume values are the conditions, which are assigned to the control commands (e.g. SET /MEDIA/PORTS/VIDEO/O2/ANALOGAUDIO.VolumedB=-96\x0d\x0a). When the rotary reaches the proper position, the action will be executed.

The control command can be sent over RS-232 or Ethernet (in this case, the IP address of the target device is needed).

LWR Volume Control Schema supports to load the LW3 command list automatically for controlling the volume (and the mute/unmute state) of the Lightware devices. Choose the proper schema (see more details about the compatibility table in Configurations of the Rotary section) and fill the audio port number.

Custom Volume Control Schema makes it possible to configure any command for controlling a third-party device.

Knob press toggles between the muted and the unmuted states. When the Custom schema is loaded, press and release event can be configure for any purpose.

Flowchart of the rotary configuration process

INFO:Customizing the rotary functions is possible with Lightware Device Contoller software (the details can be found in Configurations of the Rotary section) or with LW3 protocol commands (for more details see Volume Control Configuration section).

4.3. Inputs 2. - Automation Options

The below-listed features give an opportunity to "automate" the control system, and the Room Automation Panel reacts to the inputs automatically, user intervention is not necessary.

These inputs can be set as a condition in the Event Manager in the Software Control - Lightware Device Controller (LDC) software. They trigger the desired actions.

The real-time clock feature supports the storage of the exact time in the device. The time can be programmed as a condition in the event manager: single and weekly repetitive events may be configured with this function. Local time elements (years, months, days, etc.) help customize the proper timing of the actions.

A BR1632A battery is supplied with the product, it ensures the fluent operation of the built-in timer while the device is not powered.

The battery is designed for life-long usage in a fixed installation, so it cannot be replaced!

Real-Time Clock Settings

The flowchart below displays the correlation of the time properties. The red colored settings can be defined by the user, the others generated automatically.

Flowchart of the real-time clock configuration process

INFO:All settings of the Real-time clock is possible using the Lightware Device Contoller software (see the details in Time Settings section) or via LW3 protocol commands (in the Time Settings section).

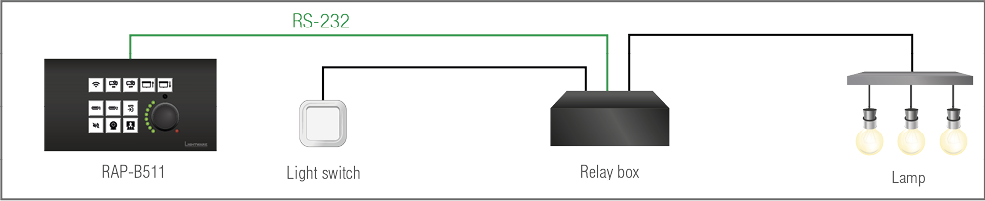

This tool is able to recognize and store the incoming RS-232 message until the previously defined string (delimiter) has arrived or the timeout has elapsed after the last data. The last incoming serial data is stored and it can trigger an action in Event Manager.

ATTENTION!The recognizer function works when the operation mode of the RS-232 port is control or command injection (in this case, one of the Ethernet socket have to be opened). For more details about the operation modes, see the Serial Interface section.

The lamp can be turned on and off both with the light switch and the RAP-B511. When the lamp is turned off by the switch, the relay box sends an RS-232 status message to the RAP-B511 to inform it that the lamp was turned off. When the lamp is controlled with the RAP-B511 the next time, the device sends the 'turn on' command to the relay box of the lamp. This example shows how to syncronize the same control function in the RAP with another device.

At first, configure the recognizer for the serial communication, after that, configure the Button1.

Step 1.Enable the operation of the recognizer, set an optimal timeout (e.g. 30 ms). Set the RS-232 operation mode to Control.

The flowcharts below show the process of the system. The blue highlight boxes display the settings connected to the RS-232 recognizer.

Turn on the lamp

Turn off the lamp

Do the following setting on the UI Config page:

Step 2.Select the Button1 and set the operation mode to Toggle. The first button press changes the interaction state to true. It happens automatically.

Step 3.Choose the TRUE feedbacks tab and click on the RS-232 message recognized condition. Write the serial message that is sent by the relay box about the lamp status in the entry field of the pop-up window (e.g. 'the lamp is turned on'). Click on Ok to save.

Step 4.Choose the FALSE feedbacks tab and click on the RS-232 message recognized condition. Write the serial message that is sent by the relay box about the lamp status in the entry field of the pop-up window (e.g. 'the lamp is turned off'). Click on Ok to save.

The RS-232 recognizer settings need to be done with Lightware Device Controller Software (see details in the RS-232 Message Recognizer section) or with LW3 protocol commands (see more information in the RS-232 Message Recognizer section).

For more information about the button configuration, see the UI Config Menu section.

DIFFERENCE:The features mentioned below are available from FW package v1.1.0b3.

The feature is almost the same as in case of the RS-232, but for the network interface: the incoming TCP messages can be processed, which may trigger actions. The combination of the TCP recognizer and the Event Manager gives numerous opportunities for creating automatic room solutions.

TCP Recognizer Example

When the Projector switches off, the button light (2) of the RAP-B511 is turned off automatically.

When the power-off process is started in the projector, it will send a message over Ethernet. That message will be recognized by the RAP-B511 and will be used as a Condition in Event Manager.

How to set up the RAP?

Step 1.Configure the recognizer for the communication by the LDC, (see the Ethernet section) or by LW3 protocol commands (see the TCP Message Recognizer section). Define the desired device as a TCP client. (The Projector is saved as 'C1' in this example.)

Step 2.Create the following event in the Event manager:

E1. When the (PWR!001 "On") message is recognized from the C1 client, the Background light of Button LED2 is set to Off state.

For more information about setting the events in LDC, see the Event Manager section.

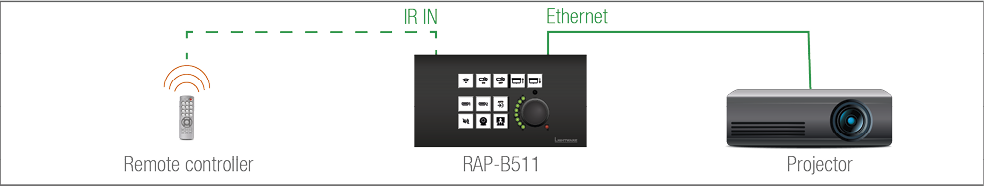

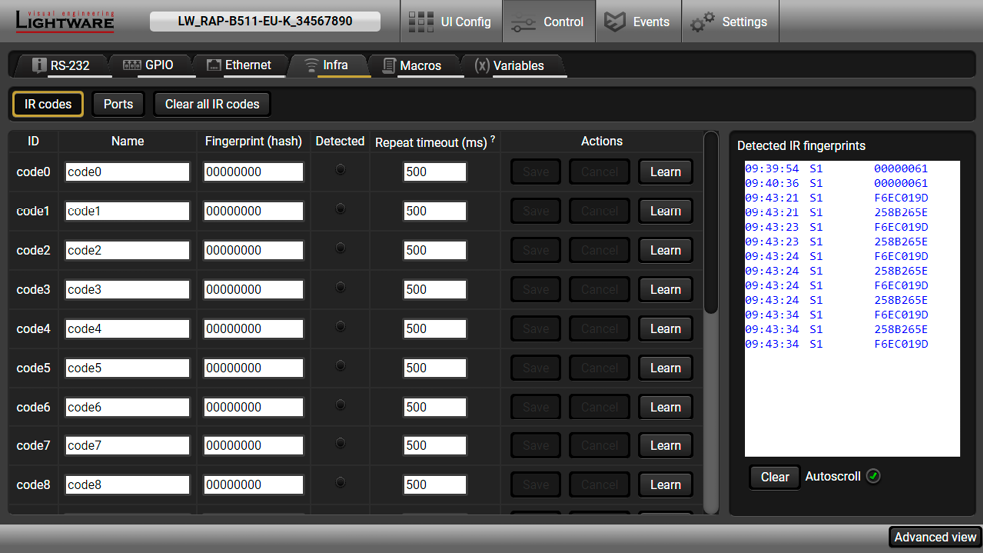

DIFFERENCE:This section relates to RAP-B511 series models only. RAC-B501 model has no built-in Infrared detector.

The RAP-B511 has a built-in IR eye with IR recognizer function. The incoming signal is stored in hash (fingerprint), and it can trigger actions in Event Manager.

INFO:All settings are available in the LDC software, more details can be found in the Infra section.

IR Recognizer Example

IR signals are sent by the Remote controller, the projector is connected to the Ethernet port of the RAP-B511.

The projector can be powered on via the RAP-B511 by using the remote controller with the following way:

▪Set an action in Event Manager: if the power button is pressed on the Remote controller, the RAP-B511 sends a control command ('Power on') to the projector via Ethernet. In this case you can control the device via the RAP-B511 remotely. See the details about the Event Manager settings in the Event Manager section.

4.3.5. GPIO Input Level Change

The GPIO (General Purpose Input/Output) port is a multifunctional input/output interface to control the RAP-B511 / RAC-B501 or third-party devices and peripherals. You can establish connection between the controller/controllable device and the RAP-B511 / RAC-B501 by the 4-pole Phoenix connector. Three pin's direction is configurable independently based on needs of the application.

When the GPIO pin is used as an input, it is able to receive feedbacks from the other device by changing the input level. The configuration is available in UI Config Menu and the Event Manager.

Outputs of the Room Automation Panel can be a feedback about the executed event (e.g. after the button press the button LED lights) or a control signal to the other device. Outputs can be set in the UI Config Menu (and in the Event Manager) in the Software Control - Lightware Device Controller (LDC) software.

4.4.1. Button LED Configuration

DIFFERENCE:This section relates to RAP-B511 series models only. RAC-B501 model is not built with buttons.

Button LEDs are customizable feedback of the user interaction or any input that is set as a condition. The LED behavior takes into consideration of the status of the interaction states. For more details about it, see the Buttons section. The button LEDs can be configured separately.

LED states

Six different LED behaviors are available:

Off / Low brightness / High brightness / Blinking / Slow blinking /Sine pulse

Default LED intensity

Low brightness and High brightness intensity can be customized in 0-5 level scale where 0 means no light, 5 means maximum intensity.

The factory default value of the low brightness: 2

The factory default value of the high brightness: 5

This setting is available in the LDC in the Front Panel Settings section or with LW3 protocol commands (for more details, see the Configure Button section).

Default LED function

The button LED can get a default function where two cases are defined:

▪LED function for true state (when the interaction state is true)

Example: Button1 is in Momentary operation mode, so when it is pressed, the interaction state changes true. If the LED function for true state is on, the button LED will turn on while it is pressed.

▪LED function for false state (when the interaction state is false)

Example: Button2 Button3, Button4 are in the same radio group. When Button2 is pressed, its interaction state changes to true and the other's interaction states change to false. If the LED function for false state is off (of all buttons in the group), the LEDs of Button3 and Button4 will turn off.

Momentarily LED function

The Button LED can get a momentarily function. This overwrites the default function for a while. Duration time has to be set if the LEDs momentarily function is off / low bright /high bright. Blinking number is required when the LEDs momentarily function is blinking.

LED function settings has to be done with Software Control - Lightware Device Controller software (in UI Config Menu section) or with LW3 protocol commands (for more details see Button LED Configuration section).

4.4.2. Rotary LEDs

DIFFERENCE:This section relates to RAP-B511 series models only. RAC-B501 model is not built with rotary switch.

Rotary LEDs always display the actual position of the rotary. For more details about it, see the RAP-B511 Series section.

4.4.3. Serial Message Sending

The Room Automation Devices can send serial messages via RS-232 port in order to control the other devices. This function can be set as an action which executed after the trigger condition (e.g. buttonpress).

Preparations and Settings

▪The RS-232 port settings (baud rate, data bits, parity, stop bits) of the connected serial devices must be the same.

▪The RS-232 port of the RAP-B511 must be in Disconnect mode. (If the target device is also Lightware unit, take care of the its operation mode, too)

▪Pay attention to the correct serial cabling (connector pinout). For more details about the cabling, see Factory Default Settings section.

The configuration is available in the UI Config Menu and the Event Manager. The details about serial message sending are available in the RS-232 Message Sending section or in the Message Sending Application Note.

4.4.4. Ethernet Message Sending

The RAP-B511 and RAC-501 devices can send TCP or UDP messages via Ethernet port in order to control the other devices. This function can be set as an action which executed after the trigger condition (e.g. buttonpress).

Preparations and Settings

▪Pay attention to the TCP/IP port no. (and have it opened) settings in the connected devices. (The Ethernet has to be enabled at the TPS and Ethernet ports.)

▪The Ethernet devices must be in the same subnet.

▪If you have problems with accessing a device over Ethernet, try to check the connection e.g. by pinging the IP address.

All settings are available in UI Config Menu and the Event Manager. The details about Ethernet message sending is available in the Ethernet Message Sending section or in the Message Sending Application Note.

4.4.5. HTTP Post and Put Message Sending

ATTENTION!This feature means posting or putting HTTP messages from the Lightware device to another device. Encrypted transmission (HTTPS) is not supported.

This feature allows sending HTTP post and put messages to the desired server IP:port no. Control commands can be set to the target device, but it is not suitable for processing the response (e.g. querying a parameter/status).

The feature is available in the LDC, see the HTTP Clients (HTTP Post and Put Message Sending) section, and by LW3 commands, see the HTTP Messaging section.

4.4.6. GPIO Output Level Change

The GPIO (General Purpose Input/Output) port is a multifunctional input/output interface to control the RAP-B511 or third-party devices and peripherals. You can establish connection between the controller/controllable device and the RAP-B511 by the 4-pole Phoenix connector. Three pin's direction is configurable independently based on needs of the application.

When the GPIO pin is used as an output, it is able to send a TTL signal the other device by changing the output level. GPIO output level change can be set as an action.

The configuration is available in UI Config Menu and the Event Manager.

GPIO Example

The projection screen is moved up and down by Relay box when the Button2 or the Button3 is pushed. Relay box is controlled by the GPIO port.

Step 1.Select the Button2 and Button3 set their operation mode to Radio Group1.

Step 2.When the Button2 is pressed, it triggers the P1 pin of the GPIO to high level (it closes the Relay and the projection screen is rolled down). Select the Button2 and choose the Turn ON actions tab. Click on the Set output state to 'High' action and set the P1 output port. Click OK to save.

Step 3.When the Button3 is pressed, it triggers the P1 pin of the GPIO to low level (it opens the Relay and the projection screen is rolled up). Select the Button3 and choose the Turn ON actions tab. Click on the Set output state to 'Low' action and set the P1 output port. Click OK to save.

ATTENTION!Please always check the electrical parameters of the devices what you want to control. The maximum current of one GPIO pin is 30 mA, the maximum total current for the three pins is 180 mA.

See the LDC settings for GPIO port in the GPIO section. See also the details about the button configuration, in the UI Config Menu section.

4.5. Settings for Control Interfaces

Technical Background

Serial data communication can be established via the local RS-232 port (Phoenix connector). Three different RS-232 modes can be set for the serial port: Disconnect, Control mode, or Command Injection; see the figure below.

Serial port diagram of Room Automation Panels

The following settings are defined:

|

|

The serial port is in Disconnect mode. |

|

|

The serial port is in Control mode. |

|

|

The serial port is in Command Injection mode. |

INFO:All settings are available in the LDC software, see details in the RS-232 section.

Only one mode can be used at a time: Disconnect, Control mode, or Command Injection mode.

Disconnect Mode

This mode is for sending control commands to a third-party (or a Lightware) device from the RAP-B511. ASCII characters and binary data in hexadecimal format can be used in this case.

Control Mode

The incoming data from the given port is processed and interpreted by the CPU. The mode allows to control the device directly. LW2 or LW3 protocol commands are accepted – depending on the current port setting.

INFO:Serial message sending is available in control mode.

Command Injection Mode

In this mode, the device works as a TCP/IP <-> RS-232 bidirectional converter. The TCP/IP data is converted to RS-232 data and vice versa. For this operation separated TCP/IP port number is defined (independent of the basic ones which are used for device control over TCP/IP).

4.5.2. Ethernet Interface

The device can be controlled via Ethernet (standard RJ45 connector). This interface supports:

▪Configure the device with Lightware Device Controller. For more information about the LDC, see Software Control - Lightware Device Controller section.

▪Control Lightware devices with LW2 and LW3 command protocols. See more details about the Lightware protocols in LW2 Programmer's Reference and LW3 Programmers’ Reference sections.

▪Establish the connection to Lightware Device Updater v2 software and perform a Firmware Update.

▪Create local network, passthrough the Ethernet data traffic.

About PoE

The Ethernet ports of the RAP-B511 are in accordance with IEEE 802.3af (PoE) standard. One Ethernet port can receive and the other one can send power over the Ethernet line. For more information about the PoE function, see Powering Options section.

INFO:PoE-compatible and not compatible devices can be connected simultaneously as the feature can be set individually on each port.

Example

The Room Automation Panel sends PoE via Ethernet to the PoE-compatible display outside the meeting room, which shows the availability of the room.

4.5.3. USB Control Interface

The device can be controlled over front panel USB mini B-type connector. The interface can be used to establish a connection to Lightware Device Controller. For more information about the LDC, see Software Control - Lightware Device Controller section.

This interface only supports LW3 protocol. See more details about the Lightware protocols in LW3 Programmers’ Reference sections.

Establish the connection via USB to Lightware Device Updater v2 software and perform Firmware Update.

DIFFERENCE:This section relates to RAP-B511 series models only. RAC-B501 model is not built with Infrared detector.

Technical background

RAP-B511 contains dedicated IR in connection and is able to receive IR signal via the built-in IR detector units. The signal is stored in hash (fingerprint)format.

With the help of the device's IR recognizer functionality you can assign actions in Event manager (for more details, see IR Recognizer section). The second option is the command injection mode (like at Serial Interface in the previous section) where you can send IR commands over LAN. Command injection mode can be turned on and off on the input port.

Port diagram of the IR interface

INFO:All settings are available in the LDC software, see settings in the Infra section.

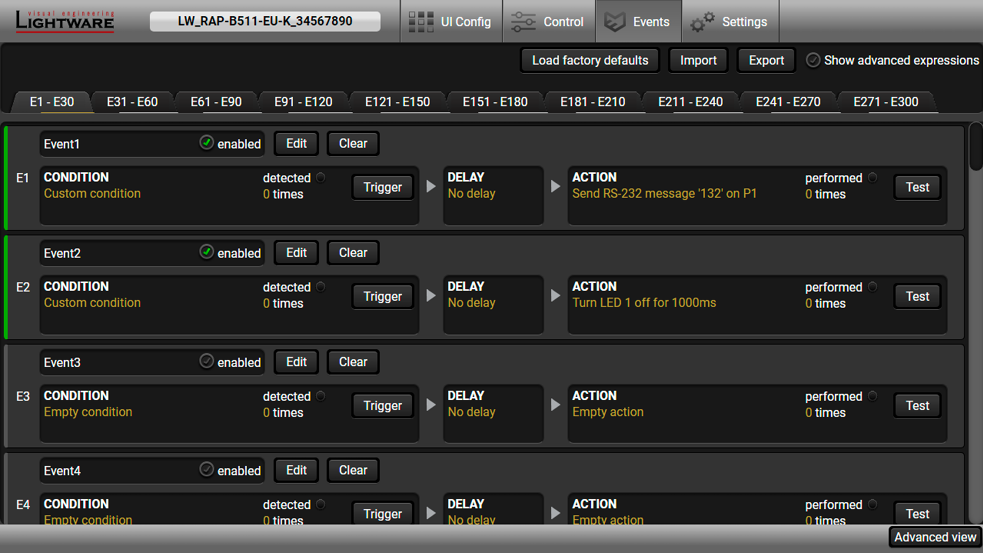

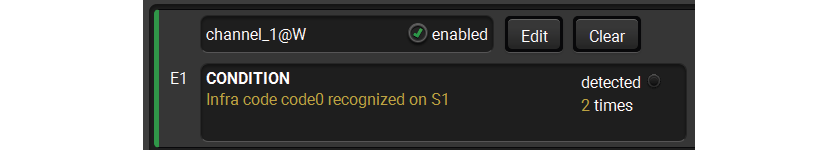

4.6. The Event Manager Feature

The Event Manager feature means that the device can sense changes on its ports and is able to react according to the pre-defined settings. Lightware Device Controller contains a user-friendly software tool and allows creating Events by defining a Condition and an Action.

Event Manager Example

See more information about the settings in the Event Manager section in LDC.

Event Manager +

DIFFERENCE:Below mentioned features are available from FW package v1.1.0b3.

The AND Operator

The practical experience has shown that there is a need to examine more conditions (up to four) as follows: if one of the set conditions becomes true (while the other conditions are fulfilled), then the set Action is launched. For example, in a meeting room we have the following situation:

▪Signal is present on an input port,

▪A GPIO pin state becomes ’low’ (by an external device).

If the two Conditions are present at the same time, the Action is launched. Just create the two Conditions into separate Events, then create a third Event, select the two Conditions and define the Action.

See the Combine Links section for the settings in LDC.

Event Manager Variables

A brand new area is opened by implementing the variables. You can create custom variables (max. 30 pcs.) in number or text format which can be used in the Event Manager. The variables can have the following properties/methods:

▪Numeric (integer) type with min/max value setting, or string-type (the type is set automatically)

▪Increment/step the numeric value,

▪Value-dependent case operations,

▪Reading and storing the value of an LW3 property into a string or a numeric variable.

The defined variables are stored in a non-volatile memory and the value is kept in case of a reboot. The new opportunities allow creating a monitoring/controlling system without connecting an additional control processor.

See the Variables section for the settings in LDC.

Condition Trigger

This improvement in the Event Manager works as if a condition is detected. When a complex control system is built, a Condition may trigger numerous Actions. A typical example is when a system is powered on and the ’ready-to-use’ state has to be loaded. In this case, there could be many actions which are based on the same condition. In order to reduce the number of the commands, you can trigger one ’key’ condition, which could start the whole process. See the Condition Triggering section for the settings in LDC.

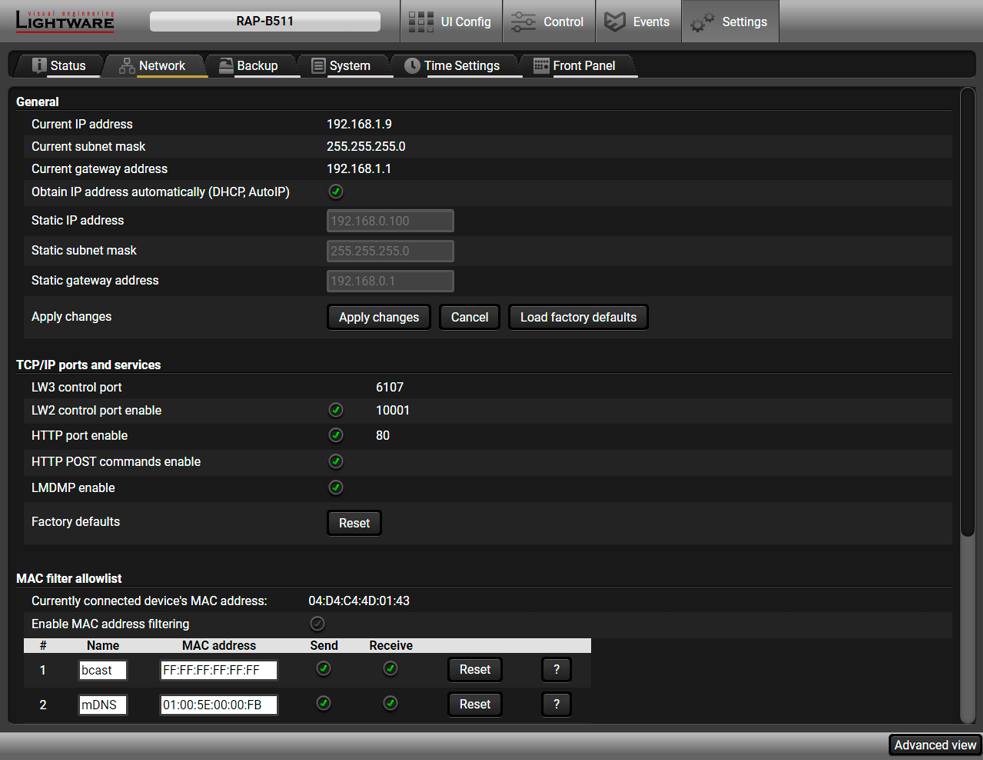

4.7. Basic IT Security

DIFFERENCE:Below mentioned features are available from FW package v1.1.0b3.

These entry-level network security improvements help to prevent unauthorized access to the Lightware device:

▪Cleartext login

▪IP Port Block

▪MAC Filtering

The Cleartext Login tool allows setting a password for login, thus, the device will not accept any command coming from an interface (RS-232, Ethernet, etc…), only the device type and the serial number can be queried without login. You can set all affected TCP/IP ports individually to enable or disable.

The IP Port Block feature is an additional protection for the Cleartext login. There are TCP/IP ports in Lightware devices which are not protected by the login, so you can disable them if necessary. Example: due to the working method of the LW2 communication, the Cleartext login does not provide protection when LW2 command is sent to the device, that is why the TCP port no.10001 shall be blocked manually.

Another level of security is the MAC Filtering tool. You can create an ’allowlist’ of network devices based on the MAC address which are allowed:

▪Controlling the device (Send option), or

▪Querying parameters (Receive option) to/from the Lightware device.

Below table shows the protection levels of these features.

|

IP Port |

Function |

MAC Filter |

Cleartext Login |

IP Port Block |

|

80 |

HTTP Post&Get |

|

- |

|

|

81 |

LW3 control (miniweb) |

|

|

- |

|

6107 |

LW3 protocol |

|

|

- |

|

800x |

Command injection (RS-232) |

|

- |

|

|

900x |

Command injection (IR) |

|

- |

|

|

10001 |

LW2 protocol |

|

- |

|

ATTENTION!Be careful when combining these functions; improper settings may cause malfunction.

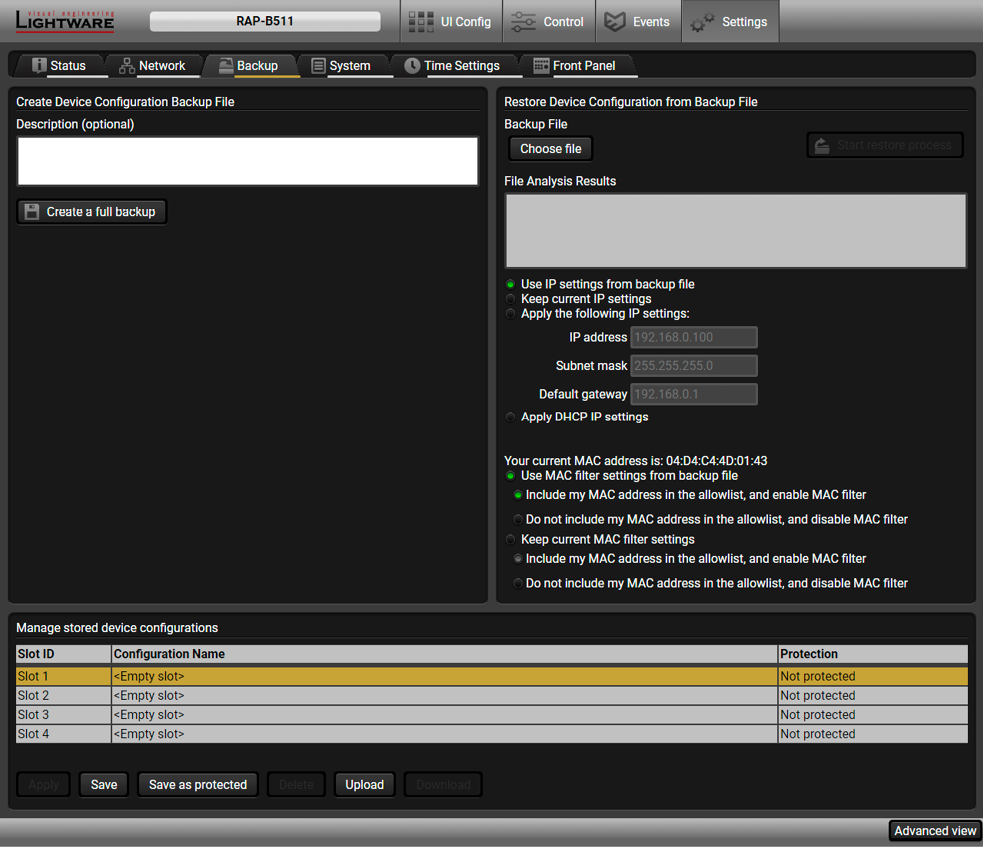

Most of these feature are available in LDC, see the Settings Menu section.

4.8. Batch Commands

DIFFERENCE:Below mentioned features are available from FW package v1.1.0b3.

These features can be used to process a group of pre-defined commands. The commands can be stored in the device as macros or you can save the commands in a plain text file and send the device by an HTTP message.

LW3 over HTTP (Command Salvo)

This feature allows the LW device to be controlled over HTTP. In this case, a batch of commands is sent over HTTP to the Lightware device for processing. Save the LW3 commands into a file, post it to the <IP_address>/protocol.lw3 file and the commands are processed immediately.

Running Macros

In this case, the command sequences (macros) are stored in the device. You can create your custom macros in a file, upload into the device and run at any time. The number of the macros depends on the device type, at most 50 macros can be saved in the device. See more information about the feature in the Macros section.

5. Software Control - Lightware Device Controller

The device can be controlled by a computer through the Ethernet and RS-232 port using Lightware Device Controller (LDC). The software can be installed on a Windows PC or macOS. The application and the User’s manual can be downloaded from www.lightware.com.

5.1. Install and Update

Installation for Windows OS

ATTENTION!The minimum display resolution shall be 1280x720.

Step 1.Run the installer. If the User Account Control drops a pop-up message click Yes.

Step 2.During the installation you will be prompted to select the type of the installation: normal and the snapshot install:

|

Normal install |

Snapshot install |

|

Available for Windows and macOS |

Available for Windows |

|

The installer can update only this instance |

Cannot be updated |

|

Only one updateable instance can exist for all users |

Different versions can be installed for all users |

Comparison of the Installation Types

ATTENTION!Using the Normal install as the default value is highly recommended.

Installation for macOS

INFO:After the installation, the Windows and the Mac application has the same look and functionality. This type of the installer is equal with the Normal install in the case of Windows and results an updateable version with the same attributes.

Mount the DMG file with double clicking on it and drag the LDC icon over the Applications icon to copy the program into the Applications folder. If you want to copy the LDC into another location just drag the icon over the desired folder.

ATTENTION!Please check the firewall settings on the macOS device. LDC needs to be added to the exceptions of the blocked software for the proper operation.

The Updating of the LDC

Step 1.Run the application.

The Device Discovery window appears automatically and the program checks the available updates on Lightware’s website and opens the update window if LDC updates are found. The current and the update version number can be seen at the top of the window and they are shown in this window even with the snapshot install. The Update window can also be opened by clicking the About icon and the Update button.

Step 2.Set the desired update setting in the Options section.

▪If you do not want to check for the updates automatically, uncheck the circle, which contains the green tick.

▪If you want to postpone the update, a reminder can be set with different delays from the drop down list.

▪If the proxy settings traverse the update process, set the proper values then click the OK button.

Step 3.Click the Download update button to start the updating.

The updates can be checked manually by clicking the Check now button.

5.2. Running the LDC

The common way to start the software is double-click on the LDC icon. But the LDC can be run by command line parameters as follows:

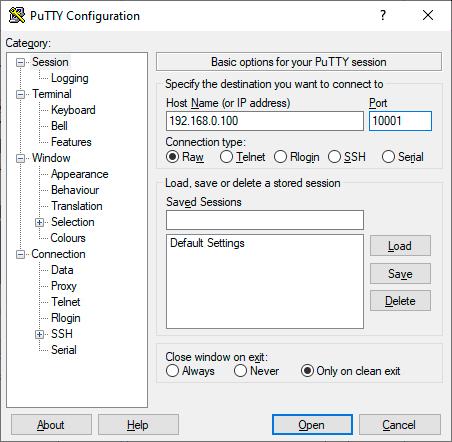

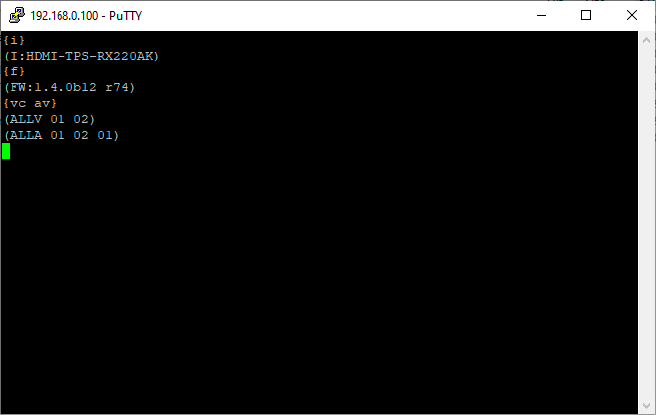

Connecting to a Device with Static IP Address

The LDC is connected to a device with the indicated static IP address directly; the Device Discovery window is not displayed. When the port number is not set, the default port is used: 10001 (LW2 protocol). For LW3 devices use the 6107 port number.

Format: LightwareDeviceController -i <IP_address>:<port>

Example: LightwareDeviceController -i 192.168.0.20:6107

Connecting to a Device via a Serial Port

The LDC is connected to a device with the indicated COM port directly; the Device Discovery window is not displayed. If no Baud rate is set the application will detect it automatically.

Format: LightwareDeviceController -c <COM_port>:<Baud>

Example: LightwareDeviceController -c COM1:57600

Adjusting the Zoom

The window can be zoomed to a specific value to fit to the resolution of the desktop (higher/lower). '1' is the default value (100%).

Format: LightwareDeviceController -z <magnifying_value>

Example: LightwareDeviceController -z 1.2

ATTENTION!The last set value is stored and applied when LDC is started without a parameter.

5.3. Establishing the Connection

Step 1.Connect the device to a computer via Ethernet (RS-232 or USB).

Step 2.Run the controller software; device discovery window appears automatically.

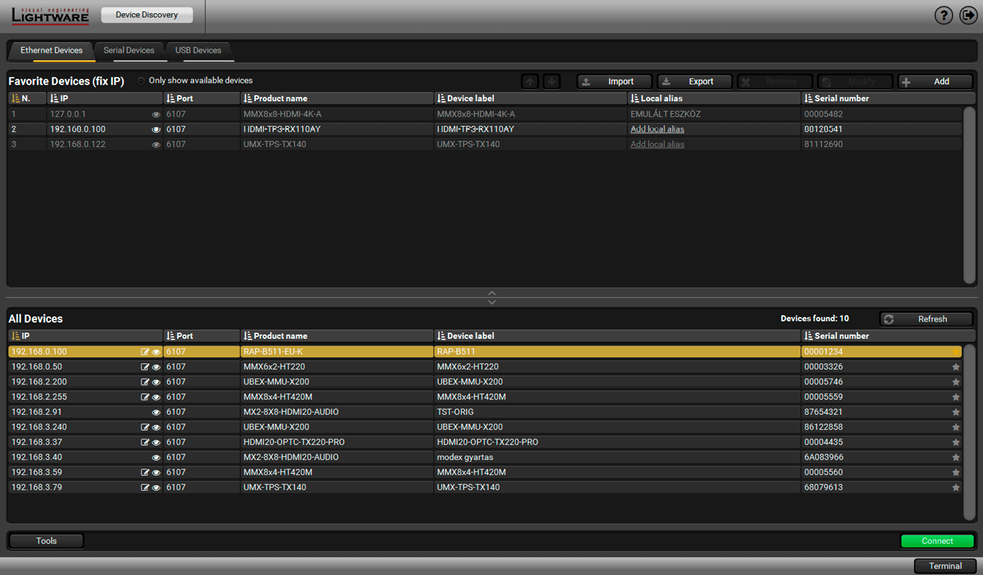

Device Discovery Window in LDC

Changing the IP Address

To modify IP address settings quickly it is not necessary to enter the device's settings/network menu, you can set them by clicking the pencil icon beside the IP address. In this window you can see only the new settings.

Identifying the Device

Clicking on the icon results the blinking of the LEDs for 10 seconds. The feature helps to identify the device itself.

The Ethernet tab consists of two lists:

▪Favorite Devices: You can add any Lightware device that is connected via Ethernet and no need to browse all the available devices. Devices can be added by pressing the Add button or marking the desired device by the  symbol in the All Devices list.

symbol in the All Devices list.

▪All Devices: The Lightware devices are listed which are available in the connected network.

Step 3.Select the unit from the discovered Ethernet devices or under Serial devices; when the device is connected through RS-232 click on the Query button next to the desired serial port to display the device’s name and serial number. Double click on the RAP-B511 or select the device and click on the Connect button.

ATTENTION!When the device is connected via the local RS-232 port, make sure that Control mode and LW3 protocol are set on the serial port.

Import/Export the List of Favorite Devices

DIFFERENCE:This feature is available only from LDC version v2.5.5.

The list of favorite devices can be exported/imported by the dedicated buttons (saved as *.JSON file). The list can be imported later (in another computer, too), but please note that the current list will be overwritten by the imported list.

Favorite Devices (fix IP)

Clicking on the grey star icon next to of the discovered devices the most used units can be saved to the Favorite devices.

ATTENTION!Only the devices set with static (fix) IP address can be saved as favorite device.

Once the device is set as favorite, the star icon will be highlighted with yellow and the device will be displayed between the Favorite Devices (fix IP) window section.

|

|

Information ribbon |

The label shows the device label which can be edited in the Settings menu - Status tab. Device discovery window can be displayed by clicking on this ribbon. Hover the mouse cursor to the information ribbon; the device label and the IP address of the device will appear as a tooltip text. |

|

|

Main menu |

The available menu items are displayed. The active one is showed with dark grey background color. |

|

|

Button Properties |

Basic button settings (e.g. button name, operation mode) can be done in this section. See more details in Button Properties section. |

|

|

Summary of the Button Interactions |

This section contains all the defined events of the selected button. For more details about it, see Button Interactions section. |

|

|

Advanced View button |

Displaying Advanced View Window, showing the Terminal window and the LW3 protocol tree. |

|

|

Configure button section |

The tabs consist of actions and conditions which can be set to the selected button. The tab denomination depends on the button operation mode. The wireframe view of the buttons can be customized by icons and text on the Style tab. For more details about it, see Configure Button section. |

|

|

Wireframe view |

Wireframe view shows the configurable button (or the rotary) with highlight color and shows the buttons in the same radio group, too. Click one to select and adjust it. |

Legend of the Wireframe View

Click the button icon on the wireframe view to display and modify the related configuration.

ATTENTION!Clicking the button icon on the wireframe view does not simulate the button click. Test Button Press button is for that purpose.

The following settings are available in the Button Properties section:

▪Button enabled: The buttons can be enabled or disabled independently of each other (when the button is disabled, pressing it will have no effect).

▪Button name: The button name can be 32 character-long, ASCII characters are allowed. Longer names are not accepted.

▪Operation mode: Three modes are available: momentary, toggle, or radio group (1-5). For more details about the operation modes, see the Buttons section.

▪Interaction state: Displays the current state of the selected button. For more information about the interaction states, see the Buttons section.

▪Test Button Press: Press the Test Button Press button to test the buttonpress (indicates a virtual button press).

▪LED enabled: LED function of the selected button can be turn on and off.

▪LED function for TRUE/FALSE state: Six default button LED state can be set: off / low bright / high bright/ blink /slow blink / sine pulse.

The LED behavior change depends on the interaction state. For more information, see the Button LED Configuration section.

INFO:The intensity of the LED brightness can be customized in the Settings menu, on the Front panel tab. For more details see Front Panel Settings section.

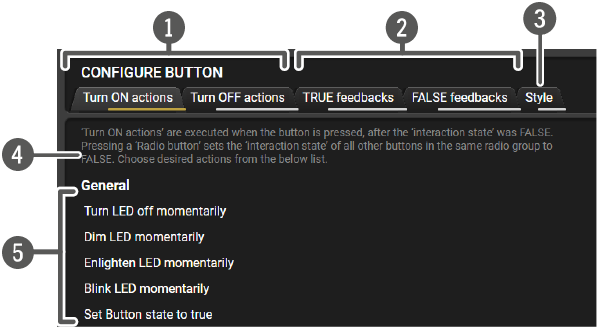

This section provides a layout where button functions can be set quick and easy.

The first two configuration tabs are for setting the Actions (outputs) of the chosen button. In this case, the trigger condition is always the same. The second two tabs are for setting the Feedbacks (conditions or inputs) and the action is fix.

The tab denomination depends on the button operation mode. A short description gives a hint to choose the proper condition or action for the selected button.

|

|

Tabs to set the action |

|

|

Tabs to set the feedback |

|

|

Tab to set the button Style |

|

|

Short description |

|

|

Action or condition list |

Summary of the actions and feedbacks tabs

|

Button operation mode |

Tab name |

Action |

Feedback (condition) |

|

Momentary |

Press actions |

Choose the desired action from the list |

Interaction state is true |

|

Release actions |

Choose the desired action from the list |

Interaction state is false |

|

|

TRUE feedbacks |

Interaction state is true |

Choose the desired condition from the list |

|

|

FALSE feedbacks |

Interaction state is false |

Choose the desired condition from the list |

|

|

Toggle |

Toggle ON actions |

Choose the desired action from the list |

Interaction state is true |

|

Toggle OFF actions |

Choose the desired action from the list |

Interaction state is false |

|

|

TRUE feedbacks |

Interaction state is true |

Choose the desired condition from the list |

|

|

FALSE feedbacks |

Interaction state is false |

Choose the desired condition from the list |

|

|

Radio group 1-5 |

Turn ON action |

Choose the desired action from the list |

Interaction state is true |

|

Turn OFF action |

Choose the desired action from the list |

Interaction state is false |

|

|

TRUE feedbacks |

Interaction state is true |

Choose the desired condition from the list |

|

|

FALSE feedbacks |

Interaction state is false |

Choose the desired condition from the list |

Button configuration steps:

Step 1.Choose the tab and click on the desired action or condition in the thematic list.

Step 2.Type the missing parameters (and the delay, if it is necessary) in the pop up window (on the right).

Step 3.Click OK to save. The configuration is saved as an Event in the Event Manager. It can be seen in the event list, numbered backwards.

Stylize the Buttons

When the button has a function, the last step is to add a text or icon to the wireframe view. This layout will appear on the Built-in Miniweb and supports the identification of the virtual buttons with the front panel.

|

|

Tab of Style config. |

|

|

Button icons (same with the device label stickers ). Click one to set for the currently selected button. |

|

|

Selected icon (highlighted with amber frame) |

|

|

Button text entry field. Maximum three rows can be displayed for one button. 30 ASCII characters are allowed for all rows. |

|

|

Click to clear the button style. |

|

|

Click to open the Miniweb page in the web browser. For more details, see the Built-in Miniweb section. |

|

|

This QR code contains the web address of the Miniweb page. It can be saved in png. |

TIPS AND TRICKS:Using the same appearance of the button with the label on the physical device helps identify them easily.

This section provides an overview of all defined events of the selected button. One line represents one event. It displays the delay time between the action and the condition, the condition or the action with the parameters, the event number, where the current setting is saved.

The  icon shows that the event was not created from the UI config page. It means that an event was set in the Event Manager, where the interaction state of the selected button was defined as an action or condition (e.g. /EVENTS/E3.Condition=/MANAGEMENT/UI/BUTTONS/BUTTON11.State=true )

icon shows that the event was not created from the UI config page. It means that an event was set in the Event Manager, where the interaction state of the selected button was defined as an action or condition (e.g. /EVENTS/E3.Condition=/MANAGEMENT/UI/BUTTONS/BUTTON11.State=true )

Click on the icon to Show advanced expression. It displays the LW3 path of the event.

TIPS AND TRICKS:If the Show advanced expression mode is not active, keep the cursor on the event line for a second, and the whole expression appears in the hint box.

The following settings are available in this section:

▪The existing events can be edited by clicking on the event line (when it is highlighted with amber). Modifying the event properties is possible in the pop-up window.

▪Click on the icon beside the event to delete it.

▪All events of the button can be copied to another button. Choose a target button by clicking on the drop-down menu and select the Copy to option.

▪All events of the button can be swapped with another button. Choose a target button by clicking on the drop-down menu and select the Swap with option.

▪Clear All button is for deleting all events of the selected button.

5.4.3. Configurations of the Rotary

Click the rotary icon on the wireframe view to display and modify the related configuration.

The jog dial knob can be configured for volume control (or other controlling purposes). Turning left and right the rotary triggers the command sending via RS-232 or Ethernet.

Mute and unmute commands are assigned to the knob press, level 0-16 commands belong to the volume setting on a 16-level scale.

Follow the instructions to set the rotary:

Step 1.Choose an interface for the (volume) command sending (via RS-232 port or via Ethernet port). When the Ethernet is selected, IP address and port number are also required.

Step 2.Choose a volume control schema: Custom or Lightware.

a)Custom schema makes it possible to send serial or Ethernet messages to the third-party (or Lightware) device depending on the rotary state. Type the desired commands into the proper entry fields.

b)Lightware schema is for controlling the volume of the analog audio levels of the chosen audio port in any Lightware device. The entry fields are inactive, because the command schema is loaded automatically after setting the parameters:

▪The target device can be selected by typing the device type or chosen from the device list/generic schema list in a drop-down menu. For more details about the generic schema see Volume Control Schema Table

▪Write the audio port number (e.g. I2 or O8)

▪Click Set to confirm. Commands are loaded into the list.

▪The Send unmute when volume changed option allows setting the volume while the controlled device is in muted state. If the option is enabled, the unmute command is sent, the LED is switched off and the volume setting command is sent. If the option is unchecked, only the volume setting is processed.

▪Save the Schema by clicking Save Configuration to Device button. The configuration is saved to Events in the Event Manager (one event for one level settings). It can be seen in the event list, numbered backwards.

Step 3.Rotary LEDs give feedback about the current position of the jog dial knob. As it is rotated right (and the volume increases), the LEDs turn on one-by-one. One level means half brightness.

Generic schemes collects the Lightware devices by the same audio setting commands.

|

Schema ID |

Device Type |

|

Generic LWR-A |

DP-TPS-TX220 DVI-HDCP-TPS-TX220 FP-UMX-TPS-TX120, TX130 HDMI-3D-OPT-RX150RA HDMI-3D-OPT-TX220 HDMI-TPS-RX110AY HDMI-TPS-TX220 MMX4x2-HDMI MMX4x2-HT200 SW4-OPT-TX240 SW4-TPS-TX240 UMX-TPS-TX120, -TX130, -TX140 WP-UMX-TPS-TX120, -TX130 |

|

Generic LWR-B |

MX2-16x16-DH-8DPi-A-R, MX2-24x24-DH-12DPi-A-R MX2-24x24-DH-24DPio-A-R, MX2-24x24-HDMI20-Audio MX2-24x24-HDMI20-Audio-R, MX2-32x32-DH-16DPi-A-R MX2-32x32-HDMI20-A-R, MX2-48x48-DH-24DPio-A-R MX2-48x48-DH-48DPio-A-R, MX2-48x48-HDMI20-A-R MX2-8x4-HDMI20-CA, MX2-8x8-DH-4DPi-A MX2-8x8-DH-8DPi-A, MX2-8x8-DH-8DPio-A MX2-8x8-HDMI20-Audio, MX2-8x8-HDMI20-Audio-L MX2-8x8-HDMI20-CA |

|

Generic LWR-C |

MMX8x4-HT420M (mixer addon) MMX8x4-HT400MC (mixer addon) |

|

Generic LWR-D |

MMX6X2-HT200 MMX6X2-HT210 MMX6X2-HT220 |

|

Generic LWR-E |

MX-FR (IB/OB-A) UMX-OPT-TX150R UMX-TP-TX100 |

|

Generic LWR-F |

UBEX-PRO20-HDMI-F110, -F120 |

|

Generic LWR-G |

VINX-120AP-HDMI-ENC VINX-120AP-HDMI-ENC-DNT VINX-210AP-HDMI-ENC VINX-110AP-HDMI-DEC |

5.5. Control Menu

RS-232 Tab in Control Menu

The following settings and functions are available (both on local and TPS serial ports):

▪Operation mode: Control, Command Injection, or Disconnected (for more details about serial interface modes see the Serial Interface section);

▪Baud rate: 4800, 7200, 9600, 14400, 19200, 38400, 57600, 115200;

▪Data bits: 8 or 9;

▪Parity: None, Odd, or Even;

▪Stop bits: 1, 1.5, or 2;

▪Command injection: enable or disable; port number; #commandinjection

▪Control protocol: LW2 or LW3; #protocol #rs232 #rs-232 #serial

▪Message sending via serial port; #message

▪Reloading factory defaults (see factory default settings in the Factory Default Settings section).

RS-232 Message Sending

The message in the field can be sent out via the current RS-232 port. Response cannot be seen in the surface.

ATTENTION!The escaping is done automatically when sending a message via this surface. When the message is an LW3 command, it has to be closed by Carriage return and Line feed, e.g.: CALL /MEDIA/VIDEO/XP:switch(I1:O1)\x0d\x0a.

This tool can be used to recognize messages coming from the RS-232 port. The message can be used as a Condition in Event manager and define an Action for it.

Definitions #message

Delimiter sequence (hex): Each message is closed by this separator (if defined).

Accept timeout (ms): When the set time is elapsed after the last received message and delimiter was not detected, the device saves the data into the Text, Hex, and Hash properties. The timeout setting is useful if there is no special or easily defined delimiter in the incoming data, but there is a time gap between the messages.

Text: The recognized message in ASCII-format.

Hex: The recognized message in hex format.

Hash: Binary data that is mapped from the original message. The length of the hash is shorter, and the same message results the same hash.

Working Method

A message got recognized from the incoming data, if one of the following occurs:

▪The set DelimiterHex is detected in the message, or

▪The set TimeOut has been elapsed since receiving the last data bit.

GPIO tab in Control menu

The GPIO port has 3 pins, which operate at TTL digital signal levels and can be controlled by LDC or protocol commands. Select a GPIO pin and under the Port settings section; the settings (pin direction and input level) are displayed on the port tiles as well:

* Highlighted with black means the current setting.

INFO:Output level can be set only in case of setting the pin direction to Output. In case of input direction the output level setting and the Toggle button is not available.

Ethernet Ports

Two ports are displayed in the Ethernet settings: PoE in Eth and PoE out Eth. You can check the status of the Ethernet line by each ports: the speed and the duplexity of the connection.

The following settings are available for each ports:

▪Enable / disable the port,

▪Reload the factory defaults.

The PoE feature can be enabled/disabled on PoE out Ethernet port.

Ports tab in the Control/Ethernet menu

HTTP Clients (HTTP Post and Put Message Sending)

ATTENTION!This feature means posting or putting HTTP messages from the Lightware device to another device. Encrypted transmission (HTTPS) is not supported.

The HTTP Clients tab allows sending HTTP post and put messages to the desired server IP:port no. Control commands can be set to the target device, but it is not suitable for processing the response (e.g. querying a parameter/status. #http

The feature is available also by LW3 commands, see the HTTP Messaging section.

HTTP Clients tab in the Control/Ethernet men

When you press the enter in the Http header or Http body text box, the \r\n is added automatically.

TCP Clients (TCP Message Recognizer)

This tab is for the preparation and monitoring interface for the TCP recognizer feature. The incoming TCP messages can be detected which may trigger Event Manager Actions. A simple example can be seen in the TCP Recognizer section. #tcprecognizer #message

TCP Clients tab in the Control/Ethernet menu

The target device has to be set as a TCP client (three clients can be set):

Step 1.Type and set the Target IP address.

Step 2.Type and set the TCP port number.

Step 3.Make sure the same TCP port is opened and Enabled in the target device.

Step 4.Press the Connect to target button.